How 24??media can Save You Time, Stress, and Money.

Table of ContentsSome Ideas on 24??media You Should KnowRumored Buzz on 24??mediaExcitement About 24??mediaAll About 24??mediaFacts About 24??media Revealed

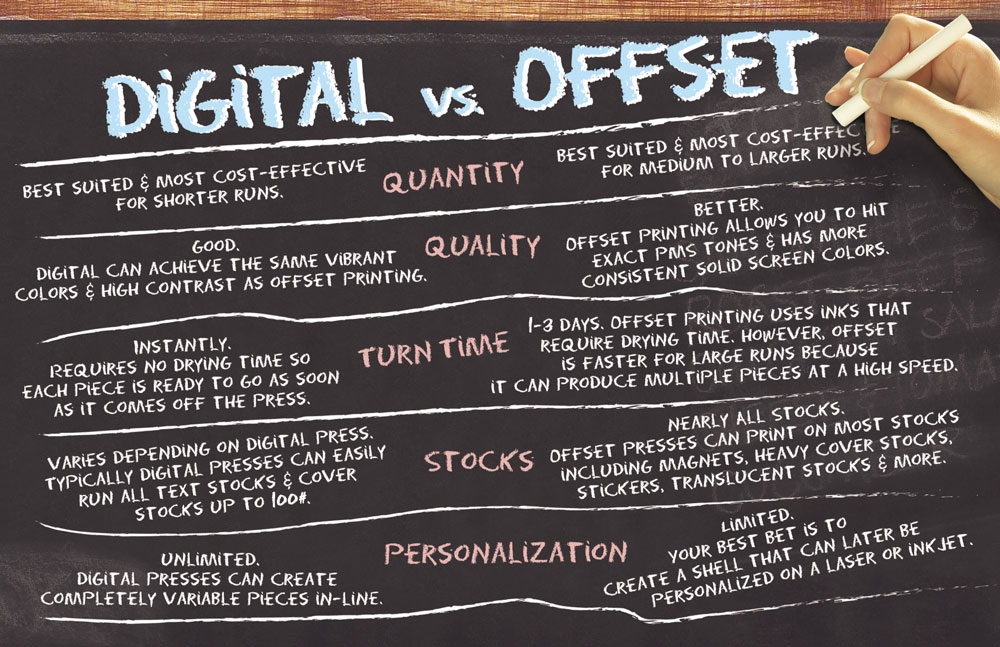

Offset, gravure printing and flexography are one of the most common kinds of traditional printing in the packaging area and each involves transferring the photo from a plate to the surface area. To do this, initially home plate needs to be produced, and it is the creation of these plates that take some time, and cost money.According to PMMI, electronic printing enables brands and suppliers to respond quickly to customer needs while boosting the supply chain, minimizing warehousing cost and waste, and appreciating faster time to market. That all noises wonderful, but exactly how does this innovation do all that? The significant differentiator of these innovations is that there are no set up charges and no plates with digital printing.

According to Wikipedia, the best difference in between electronic printing and typical techniques such as lithography, flexography, gravure, or letterpress is that there is no requirement to change printing plates in electronic printing, whereas in these analog printing approaches home plates are repeatedly replaced. This results in quicker turnaround time and decreases price when using digital printing.

Rapid manufacturing implies obtaining your item to market much faster. It additionally indicates it's easier and faster to make changes later, when you transform a recipe, add a SKU, or develop seasonal packaging. Digital printing is very flexible, so it's easy to make modifications to the bundle layout promptly. All of it returns to home plates.

Get This Report about 24??media

Much more inventory can indicate more waste later on. With conventional printing approaches, short-run printing is simply not possible. Because a terrific layout can make or break your product, electronic printing constantly produces top notch, clear and vibrant graphics each time. Digital printing on versatile bags adds the intense, vivid, and precise graphics that almost beckon customers to reach out and touch them.

Filling ... Are you familiar with the advantages of electronic printing? Both offset and electronic printing have their location in the printing sector.

In this post, we will certainly discuss the advantages of digital printing to assist you much better understand if electronic printing is just what you require. Merely placed - electronic printing prints product straight onto the paper.

The Basic Principles Of 24??media

As electronic printing regularly advances, it provides much more possibilities and higher result top quality each day. In some instances, the print high quality can be as high as to counter printing. As years pass, electronic print is ending up being much more available, with improved rate and high quality. This is just the factor printing firms are adding digital printing to their offer.

For offset printing, if any kind of blunder goes undetected before developing home plates, there will certainly be a high cost of developing a new one. But, with digital printing, this is not the instance. Although everyone always hopes there will certainly be indisputable, knowing the expense of remedying them if they occur is always a great idea.

This indicates every item will look the same, so the possibility you will need to dispose of any of them due to incongruities is low. Because a proofing example is printed on the same maker as the product itself, color proofing is very exact. Any kind of troubles with shade will certainly show up on the proof, and therefore it will certainly be possible to transform it prior to printing the entire run.

Some Ideas on 24??media You Should Know

Digital printing, on the other hand, requires minimal setup. This is excellent when you are in a rush to obtain your published products.

This implies more ask for digital on-demand print production. Every customer appreciates an individualized message. Among the advantages of digital printing is that customizing your marketing products could not be less complicated. Cost-efficient, smaller sized batches allow companies to tailor each order. Have a back-to-school sale? Make a leaflet to target moms and dads and one more one to target the pupils.

Digital printing is the best option for variable data printing, like custom codes and addresses on straight mail. With digital printing, it is less troublesome to make last-minute changes to your design. Occasionally the most effective form of interaction is not digital. In these situations, counting on digital printing can ensure these orders have a marginal environmental impact.

Some Known Details About 24??media

There is likewise no need to clean up home plates after printing. The advantages of electronic printing consist of that there is no waste from extra or leftover ink, paper, or chemicals due to the fact that just what's needed obtains printed. - for extremely short runs, digital printing is the method to go, undoubtedly.

Gone are the days of complex configurations and lengthy turnaround times - digital printing has changed the print market. The printing world has come a long method considering that the days of Gutenberg's printing machine. The brand-new regular is streamlined processes and cost-effective services for printing onto virtually anything you can think about.